STUD WELDING

WHAT IS STUD WELDING?

Drawn Arc Stud Welding

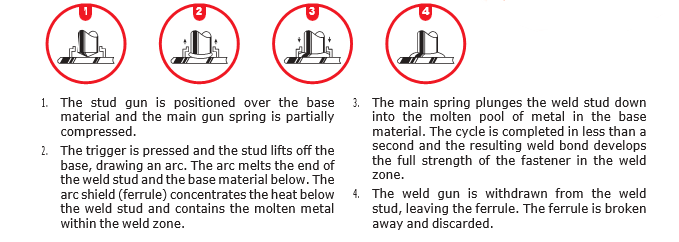

Stud welding, also known as drawn arc stud welding, is generally used to weld large diameter fasteners to rougher and thicker base metals. Arc studs may be almost any shape and there are literally hundreds, however, they must have one end of the fastener designed for arc welding. Mild steel, stainless steel, and aluminum are applicable materials for arc stud welding. Stainless Steel 304-316.

Stud Welding Guidelines

- Set appropriate time for the weld base diameter.

- Set appropriate amperage for the weld base diameter.

- Ensure that the negative polarity is to the stud gun.

- Align accessories so they are centered and adjust legs so that 3/16″ to 1/4″ of the stud protrudes beyond the ferrule.

- Ensure a good, clean ground connection.

- Keep work surface relatively clean so that impurities don not affect weld.

- Keep studs and ferrules clean and dry.

- Test welds at the beginning of each shift or change in stud (AWS Bend Test).

- Check burn off (1/8″ to 3/16″ depending on stud diameter).

- Check weld fillet (360 degrees).

- Visually inspect all welds.

Categories Fasteners, Rods & Nuts

Product Description